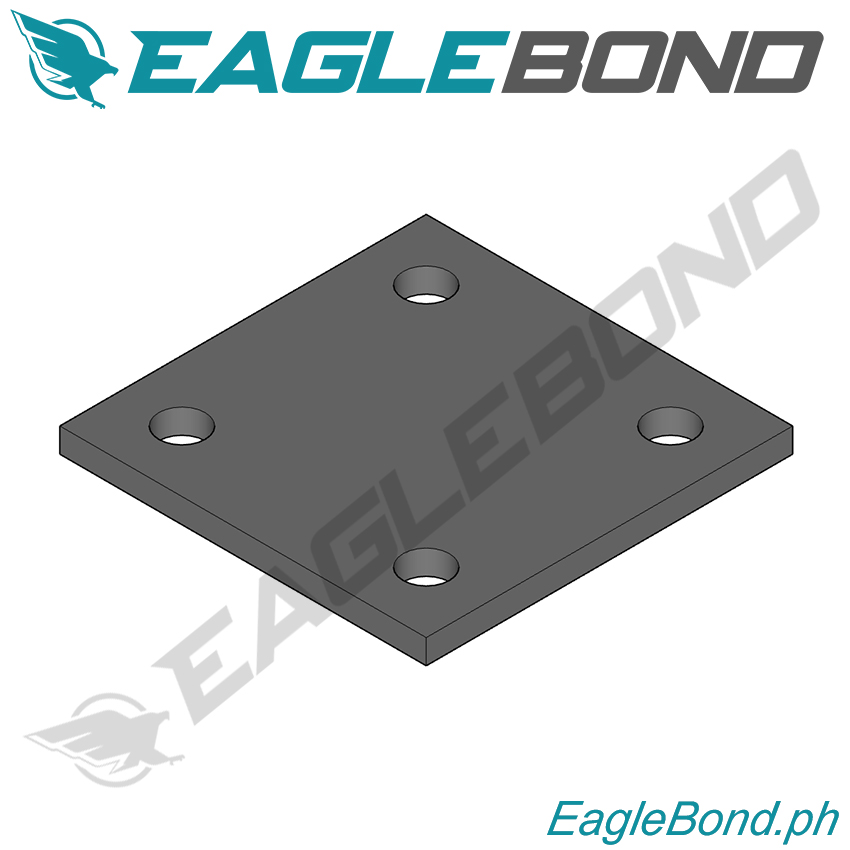

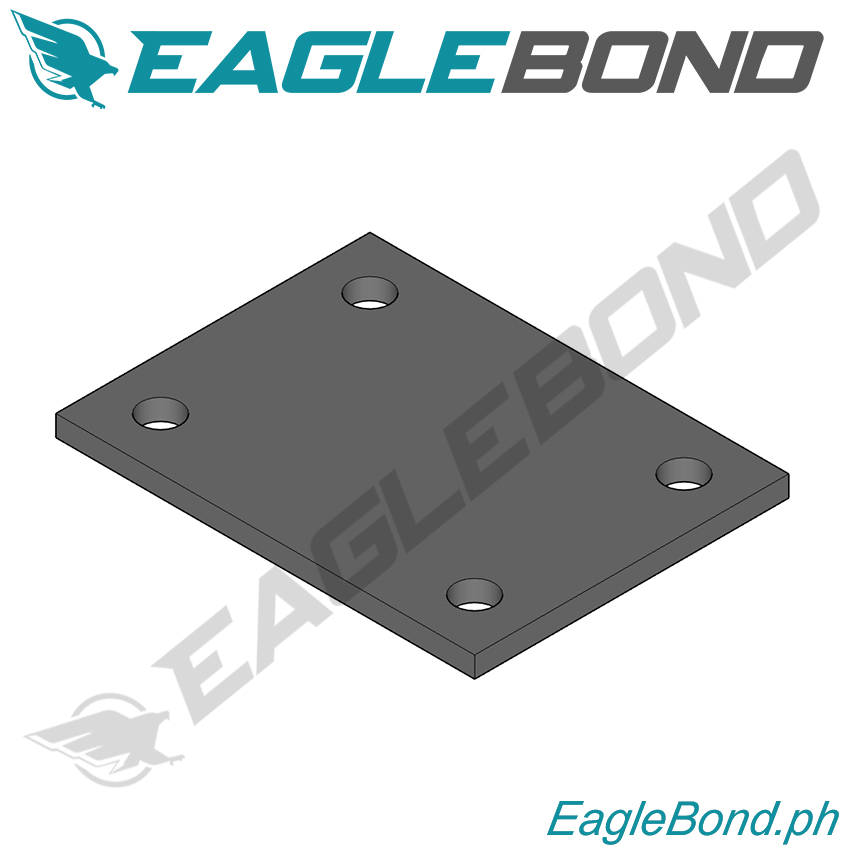

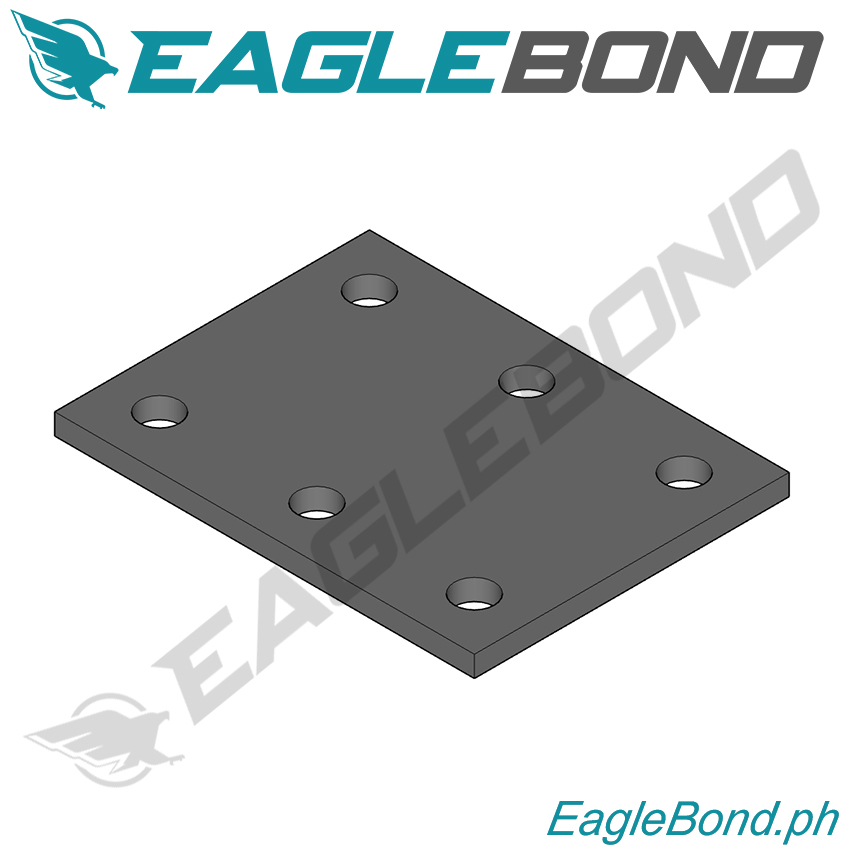

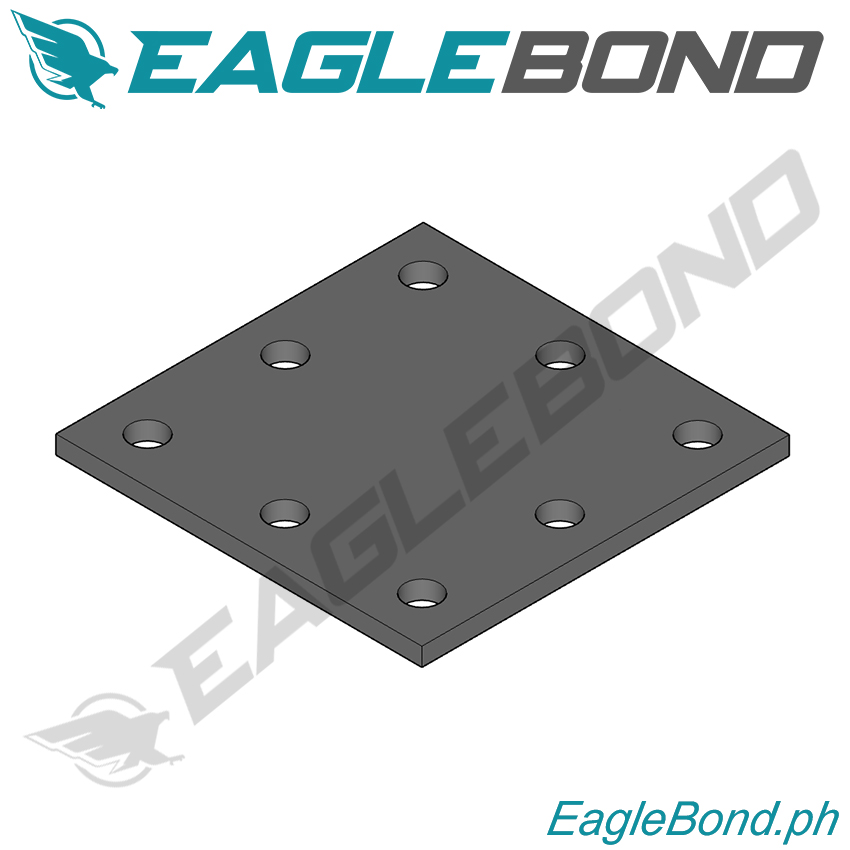

Plate A36 With Holes – Full Description

Product Description: Plate A36 with pre-drilled holes is a versatile steel plate crafted from ASTM A36, a low-carbon steel alloy known for its strength, durability, and exceptional workability. Available in various shapes—such as square, rectangular, circular, or custom cuts—this plate is designed with pre-punched holes for applications requiring specific fastening or mounting needs. It’s available in a variety of materials, including stainless steel, black iron, and galvanized options, including standard galvanized and hot-dip galvanized, each providing unique advantages depending on the application and environment.

Use and Purpose: The pre-drilled holes in Plate A36 make it particularly useful in structural, fabrication, and mechanical applications where fasteners are needed. These plates are often used in projects that require bolts, rivets, or other fastening mechanisms to connect or mount components. Common applications include mounting base plates, industrial machinery, structural frameworks, and building supports. The pre-punched holes offer ease of installation, making this product especially convenient for projects requiring speed and precision.

Key Features:

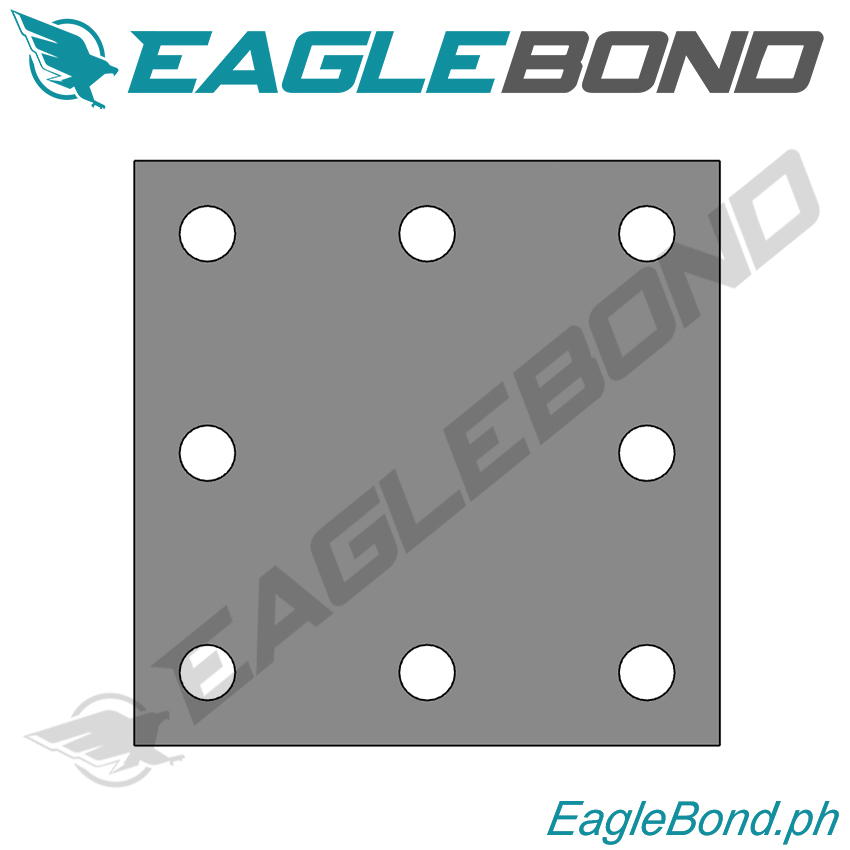

- Pre-Drilled Holes: Plates come with pre-punched holes, which are ideal for fastening or connecting other components.

- Variety of Shapes: Available in multiple shapes (square, rectangle, circle) to fit different applications.

- Material Options: Offered in stainless steel, black iron, and galvanized coatings (standard and hot-dip).

- High Strength and Durability: Known for load-bearing capacity and long-term durability.

- Corrosion Resistance: Galvanized options provide excellent protection against rust, especially in outdoor applications.

- Easy to Work With: Designed for easy installation, especially in applications requiring fasteners or bolts.

Topics to Discuss to Know the Importance of Using Plate A36 With Holes:

- Variety of Shapes for Application Flexibility: Plate A36 is available in different shapes—square, rectangular, and circular—that cater to various structural or industrial needs. This flexibility makes it easier to match the plate with the specific dimensions required by a project. Whether it’s for base plates, mounting brackets, or machinery parts, these shapes allow for seamless integration into different setups.

- Material Options and Coatings:

- Stainless Steel: Offers superior corrosion resistance, which is crucial for outdoor or marine environments. It ensures longevity and durability in harsh conditions, reducing maintenance costs and ensuring reliability.

- Black Iron: This option provides a cost-effective yet strong solution for indoor applications where moisture is not a major concern. It’s also easy to work with and can be coated if additional protection is needed.

- Galvanized Iron: Comes with a zinc coating that protects against rust and corrosion, making it ideal for outdoor or exposed environments. Standard galvanized is sufficient for many outdoor uses, while hot-dip galvanized provides enhanced protection in extreme environments like coastal or industrial areas where corrosive agents are common.

- Pre-Drilled Holes for Easy Installation: The pre-drilled holes make installation faster and easier, as they eliminate the need for manual drilling on-site. This feature is particularly important in large construction projects or industrial applications where efficiency and precision are required. The pre-punched holes allow for quick attachment of bolts, screws, or other fasteners, ensuring a tight, secure fit.

- Versatility Across Applications: The A36 plate is highly versatile and can be used in many sectors, including:

- Structural Applications: Used as base plates, flanges, or mounting plates for columns, beams, or other structural components.

- Machinery and Equipment: Often used in industrial machinery as mounting plates or brackets that require fastening to larger structures.

- Fabrication Projects: Ideal for metal fabrication, including welding and bolting, in custom projects such as frames, supports, or brackets.

- Construction and Infrastructure: Widely used in construction for supporting structures, bridges, and infrastructure projects where fastening systems are needed.

- Strength and Durability in Various Conditions: ASTM A36 steel provides a high strength-to-weight ratio, making it a reliable option for supporting heavy loads in structural projects. The material is also highly durable, maintaining its integrity over long periods, even in harsh conditions. Discussing its strength is important for projects where safety and load-bearing capacity are critical.

- Corrosion Resistance for Outdoor and Exposed Projects: Corrosion resistance is a key factor for outdoor applications. Stainless steel and galvanized options provide superior protection against rust and environmental wear. For example, hot-dip galvanized plates are often used in coastal environments where saltwater can rapidly corrode untreated steel. In environments where high moisture or chemicals are present, the choice of galvanized or stainless steel ensures the longevity of the structure.

- Weldability and Machinability: A36 steel is known for its excellent weldability, making it a great choice for custom fabrication projects. It can be easily cut, drilled, or welded into different configurations, allowing it to fit a variety of applications with minimal effort. This ease of use adds to the plate’s versatility and popularity in construction and industrial settings.

- Customizable for Specific Needs: Though the plate comes with pre-drilled holes, additional modifications can be made if needed. This allows contractors to adapt the plate to unique specifications for specific projects, whether in building frameworks, mounting machinery, or securing structural components.

Material and Coating Options:

- Stainless Steel: Corrosion-resistant, ideal for harsh and corrosive environments.

- Black Iron: Cost-effective, suitable for dry indoor applications.

- Standard Galvanized: Good for outdoor use, provides protection against rust.

- Hot-Dip Galvanized: Offers the highest level of corrosion resistance, particularly useful in extreme environments like coastal areas or industrial settings.

Conclusion:

Plate A36 With Holes is an essential component in many structural and industrial projects. Its pre-drilled holes, strength, material versatility, and ease of installation make it an invaluable choice for contractors and fabricators. Whether in construction, machinery, or industrial fabrication, this plate ensures strong, secure, and reliable connections for critical components. The choice of materials and coatings further enhances its suitability for various environments and applications.