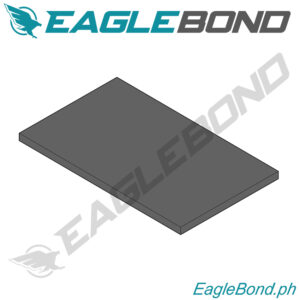

Plate A36 No Holes – Full Description

Product Description: Plate A36 No Holes is a versatile, hot-rolled steel plate made from ASTM A36 steel, a low-carbon alloy that is known for its strength, durability, and excellent workability. These plates come in various shapes—square, rectangular, circular, and custom cuts—to suit different applications, making them ideal for a wide range of structural and industrial uses. The plate is available in multiple materials, including stainless steel, black iron, and galvanized coatings like standard galvanized and hot-dip galvanized, each providing specific advantages depending on the environment and project requirements.

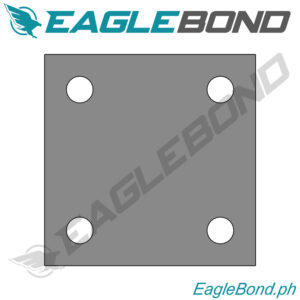

Use and Purpose: A36 plates without pre-drilled holes are designed for applications that require custom hole placement or cutting to meet specific project needs. They are widely used in construction, fabrication, and industrial sectors where structural integrity, weldability, and flexibility are crucial. Common applications include base plates, mounting plates, structural support, machinery parts, and components in buildings, bridges, and equipment.

Key Features:

- Material Options: Available in stainless steel, black iron, and galvanized (standard and hot-dip).

- Shapes: Offered in various shapes (square, rectangle, circle) to meet diverse application needs.

- No Pre-Drilled Holes: Allows custom hole configurations and cutting based on specific project requirements.

- High Strength and Durability: Known for its load-bearing capacity and long-lasting performance in both indoor and outdoor environments.

- Weldability: Easily welded to other steel components, making it a go-to material for fabrication projects.

Topics to Discuss to Know the Importance of Using Plate A36 No Holes:

- Available Shapes for Versatility: The availability of different shapes such as square, rectangular, and circular allows A36 plates to be adapted to a wide variety of structural and industrial applications. Whether it’s for large construction projects, machinery, or smaller custom fabrication work, these various shapes make it easy to find the right fit for specific needs.

- Material Options and Coatings:

- Stainless Steel: Offers exceptional corrosion resistance, making it ideal for projects in wet or corrosive environments such as coastal areas, marine applications, or industrial plants. Stainless steel provides a long-lasting and low-maintenance solution for structural needs.

- Black Iron: A cost-effective option that provides high strength and good weldability. Black iron plates are suitable for indoor and dry environments where exposure to moisture is limited. They can also be coated for added protection.

- Galvanized Iron: The zinc coating provides superior rust protection, making these plates a great choice for outdoor applications. The standard galvanized coating works well in moderately corrosive environments, while the hot-dip galvanized option offers enhanced corrosion resistance for more aggressive conditions like coastal or highly humid environments.

- Customization Flexibility: Since these plates come with no pre-drilled holes, they offer complete flexibility to fabricators and contractors. Holes can be drilled according to exact requirements, making these plates ideal for projects where precise dimensions and designs are essential. This feature is particularly useful in construction and industrial machinery.

- Strength and Durability in Structural Applications: A36 plates are known for their excellent strength-to-weight ratio, which is essential in structural applications where load-bearing capacity is critical. This makes them ideal for supporting structures like beams, columns, and frames. They can handle heavy loads while maintaining structural integrity.

- Corrosion Resistance: Discuss the importance of corrosion resistance for projects in challenging environments. Galvanized and hot-dip galvanized plates provide long-lasting protection against rust and wear, significantly extending the lifespan of the structure and reducing maintenance costs. Stainless steel offers superior rust resistance in highly corrosive conditions, ensuring durability in even the toughest environments.

- Ease of Fabrication: One of the key benefits of A36 plates is their excellent weldability and machinability. They are easy to cut, weld, and shape, making them suitable for a wide range of fabrication projects. The plates can be customized on-site, which adds to their versatility in construction, infrastructure, and industrial projects.

- Wide Range of Applications:

- Construction and Structural Support: A36 plates are commonly used in building frameworks, bridge components, and other structural supports where strength and reliability are crucial.

- Machinery and Equipment: These plates are often used as base plates or mounting plates in industrial machinery, providing a sturdy and durable surface.

- Infrastructure Projects: From road construction to pipelines, A36 plates are a foundational element in many infrastructure projects.

- Durability and Long-Term Performance: A36 steel plates offer long-term durability in a variety of conditions. Whether exposed to the elements or used in high-stress industrial applications, these plates maintain their structural integrity and resist wear over time, ensuring that projects remain safe and sound for years.

By offering these insights, you can convey the value and importance of using Plate A36 No Holes in construction and industrial applications. The choice of material, shape, and coating will depend on the specific requirements of the project, but all options provide flexibility, strength, and longevity, making this product an essential building material.