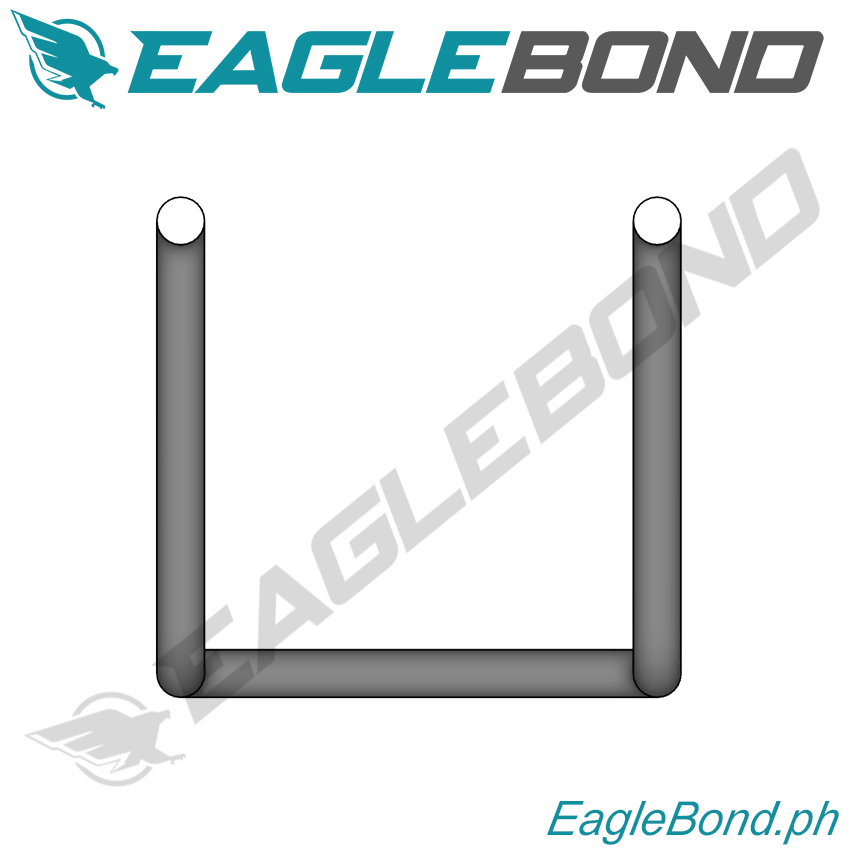

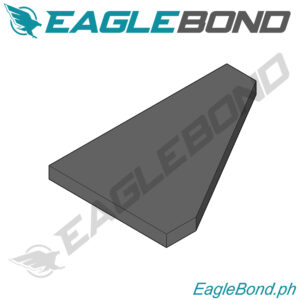

Ladder Rung

Product Description: A ladder rung is a crucial component used in ladders for both industrial and construction purposes. It provides durable and safe steps for workers, ensuring secure access to elevated areas. Ladder rungs come in different materials—stainless steel, black iron, and galvanized options—each tailored to specific environmental conditions and durability requirements. Coatings such as galvanized and hot-dip galvanized further enhance corrosion resistance, making these ladder rungs versatile for indoor, outdoor, and industrial use.

Use and Purpose: Ladder rungs serve as the horizontal steps in ladders, offering stable footing for workers climbing to heights. They are designed for installation in permanent ladder systems, safety cages, or even temporary setups like scaffolding. The various material and coating options ensure their suitability in different environments, from corrosive industrial areas to outdoor construction sites. Their robust construction ensures a long service life, even under heavy use.

Key Features:

- Material Options: Stainless steel, black iron, and galvanized iron (including hot-dip galvanized) for enhanced durability.

- Corrosion Resistance: Galvanized and hot-dip galvanized coatings provide protection against rust, essential for outdoor or wet conditions.

- Non-Slip Design: Textured surfaces minimize the risk of slipping, promoting safety in demanding work environments.

- High Load Capacity: Designed to support substantial weight loads, ensuring stable use even in heavy-duty industrial applications.

Topics to Discuss to Know the Importance of Using Ladder Rungs:

- Material Selection:

- Stainless Steel: Ideal for high-corrosion environments or areas requiring exceptional durability. Stainless steel is resistant to rust and chemical exposure, making it perfect for long-term use in industrial or coastal settings.

- Black Iron: Offers strength at a lower cost. Suitable for applications where exposure to moisture is minimal. It provides durability and is economically efficient for less corrosive environments.

- Galvanized Iron: This coating involves dipping iron in molten zinc, offering protection against corrosion. Standard galvanized ladder rungs are suitable for outdoor and industrial environments with moderate exposure to moisture.

- Hot-Dip Galvanized: Provides a thicker layer of zinc coating, delivering superior corrosion resistance compared to standard galvanization. Hot-dip galvanized rungs are preferred for highly corrosive environments, such as marine applications or where heavy rainfall occurs.

- Corrosion Resistance: The longevity and safety of ladder rungs depend significantly on their resistance to rust. Galvanized and hot-dip galvanized rungs are essential for outdoor use, preventing rusting over time and ensuring the structure remains safe for extended periods. Discuss how choosing the right material for the environment (e.g., stainless steel for coastal areas) can reduce maintenance and extend the lifespan of the ladder.

- Safety Standards and Compliance: Ladder rungs must meet industry safety standards, particularly in industrial settings where worker safety is paramount. Non-slip surfaces help prevent falls, and the load-bearing capacity ensures they can handle the weight of workers with tools or equipment. Ensuring compliance with safety regulations is critical for liability and safety purposes.

- Durability and Longevity: In high-traffic areas or environments exposed to chemicals, choosing materials like stainless steel or hot-dip galvanized rungs ensures the ladder system remains functional without constant repair or replacement. Durable ladder rungs save time and money over the long term by reducing the need for maintenance and ensuring safe operation for years.

- Coating Technology: Discuss how galvanized coatings provide a durable shield against the elements, with hot-dip galvanization offering even more extensive protection. This is particularly important for outdoor applications where exposure to rain or salty environments is high. The right coating can significantly extend the lifespan of the ladder rung.

By discussing these elements, you can demonstrate how selecting the right ladder rung material and coating impacts safety, durability, and long-term cost efficiency.